PaveLEA comparison with CIRCLY

- A comparison of the strains at the critical locations (as described in AGPT02-24) for various different pavement configurations is detailed below. The analysis follows the same process adopted by the Austroads project AP-T199-12 in the validation of APADS, which is the AustPADS analysis engine. However, Single Axle Single Tyre (SAST) loading is also compared.

- As PaveLEA does not use the exact same algorithms as CIRCLY, there are occasionally some minor differences in strains between PaveLEA and CIRCLY. However these differences, generally will not affect the pavement design i.e. results in a difference in pavement thickness of less than 5mm, which is less than typically construction tolerances.

- Spray Seal Surfaced Unbound Granular Pavements

- As per AP-T199-12, the pavement configurations that were compared for spray seal surfaced unbound granular pavements had the following inputs:

- subgrade vertical moduli of 20 MPa, 30 MPa, 40 MPa, 50 MPa, 70 MPa, 100 MPa, 150 MPa and 200 MPa

- granular thicknesses from 100 mm to 1000 mm, in 25 mm steps

- top granular modulus of 350 MPa.

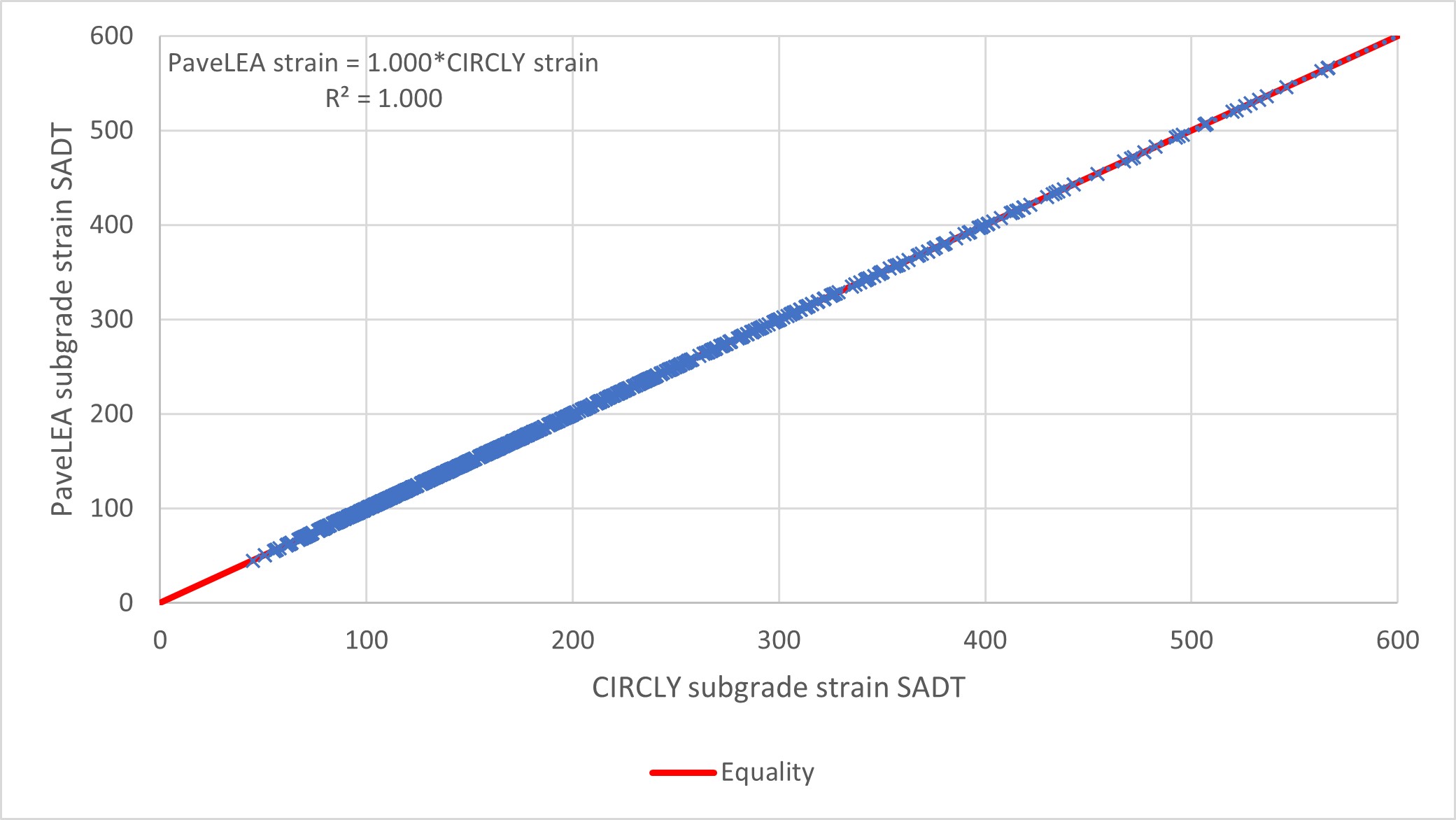

- The figure below shows the calculated maximum vertical compressive strain at the top of the subgrade for PaveLEA vs CIRCLY.

- Asphalt Surfaced Unbound Granular Pavements

- As per AP-T199-12, the pavement configurations that were compared for asphalt surfaced unbound granular pavements had the following inputs:

- subgrade vertical moduli of 30 MPa, 50 MPa, 100 MPa and 150 MPa

- granular thicknesses from 100 mm to 400 mm, in 100 mm steps

- normal quality granular material (maximum modulus of 350 MPa)

- asphalt thicknesses of 25 mm, 50 mm, 100 mm, 150 mm, 200 mm, 300 mm and 400 mm

- asphalt moduli of 1000 MPa, 3000 MPa and 5000 MPa.

Note: 25 mm asphalt is not included in the asphalt figures as AGPT02 states "the mechanistic-empirical design model has not been validated for granular pavements having asphalt surface layers less than 40 mm thick".

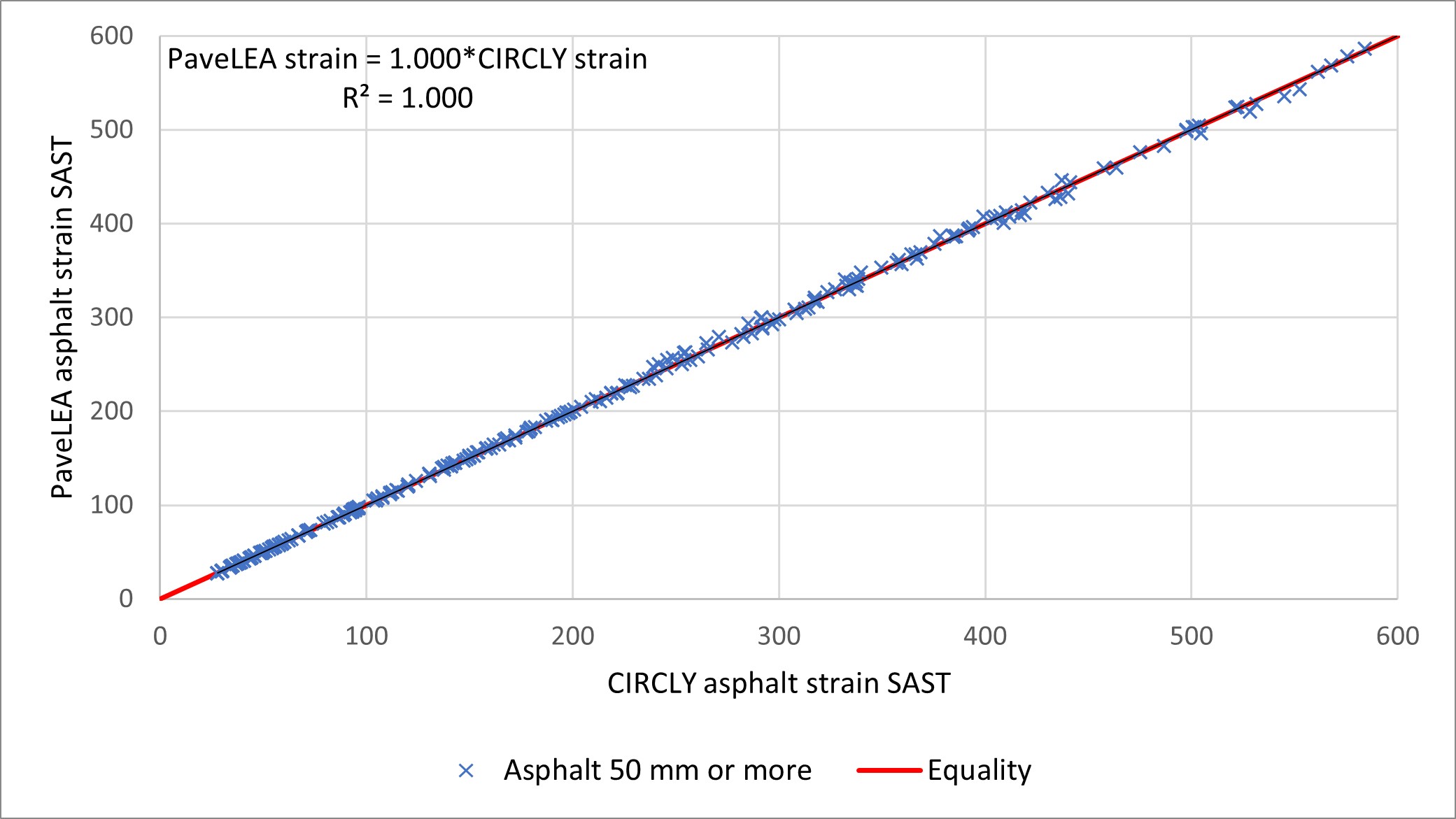

- The figure below shows the calculated maximum tensile strain at the base of the asphalt for a Single Axle Single Tyre (SAST) for PaveLEA vs CIRCLY.

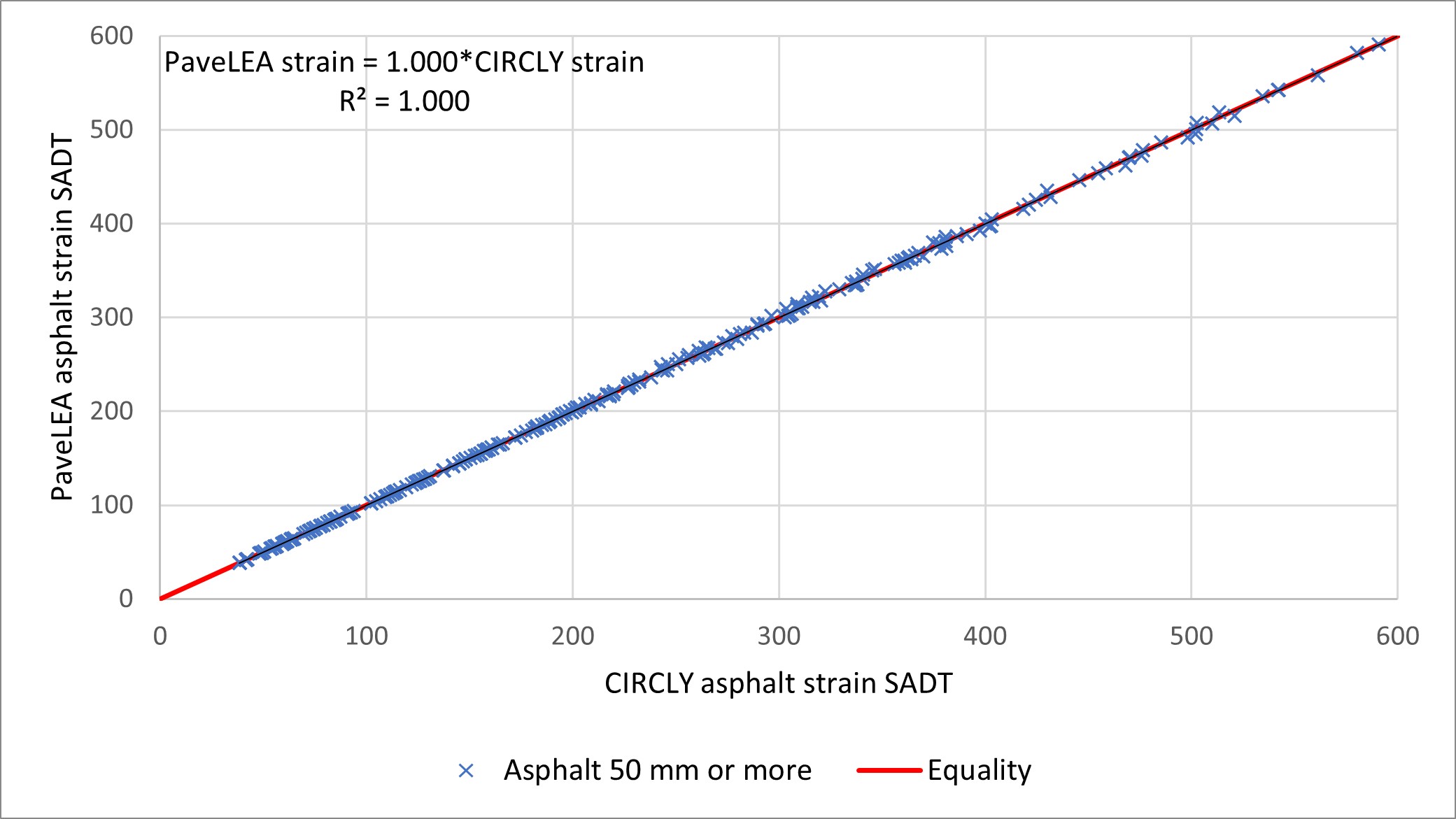

- The figure below shows the calculated maximum tensile strain at the base of the asphalt for a Single Axle Dual Tyre (SADT) for PaveLEA vs CIRCLY.

- The figure below shows the calculated maximum vertical compressive strain at the top of the subgrade for PaveLEA vs CIRCLY.

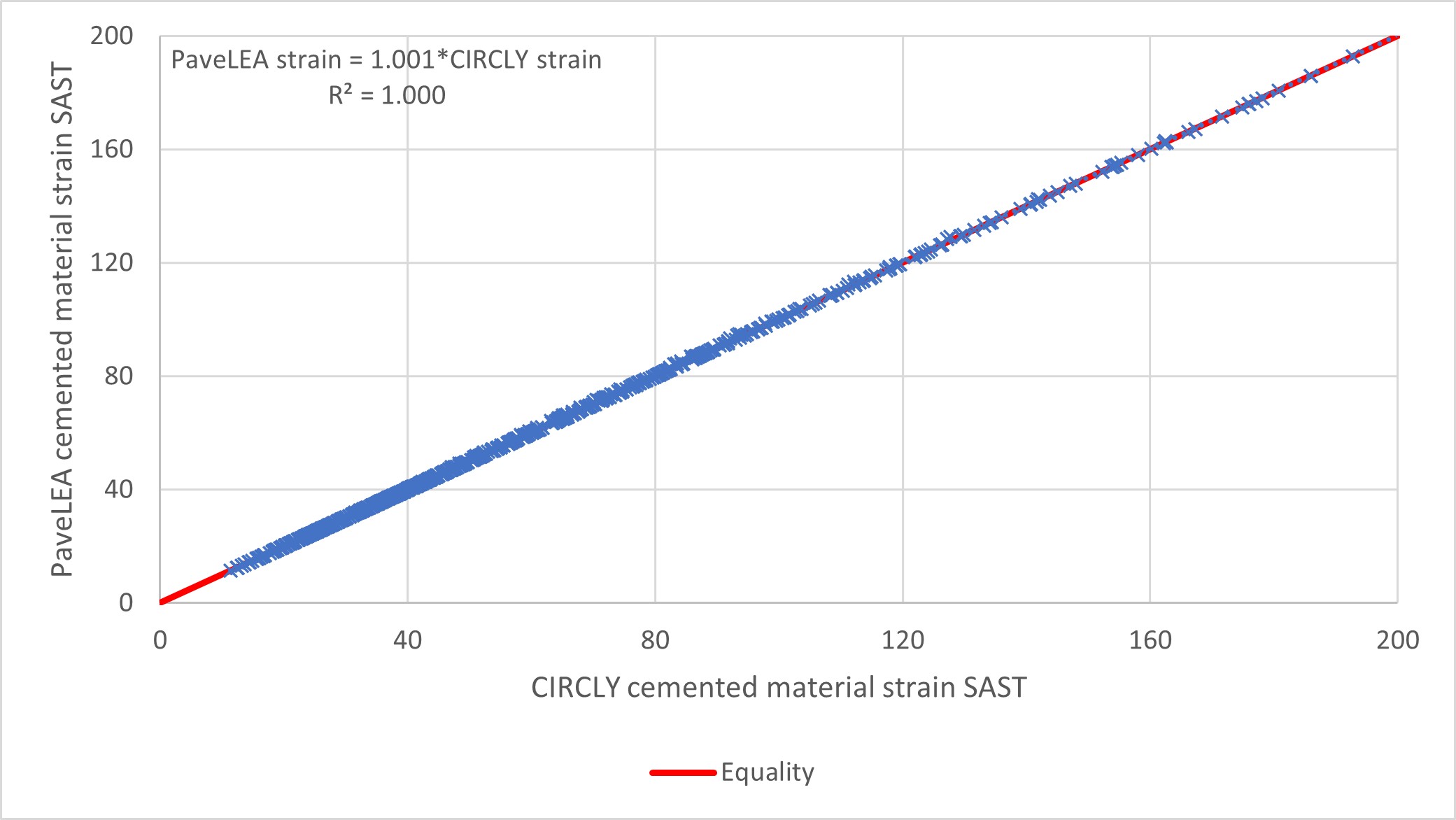

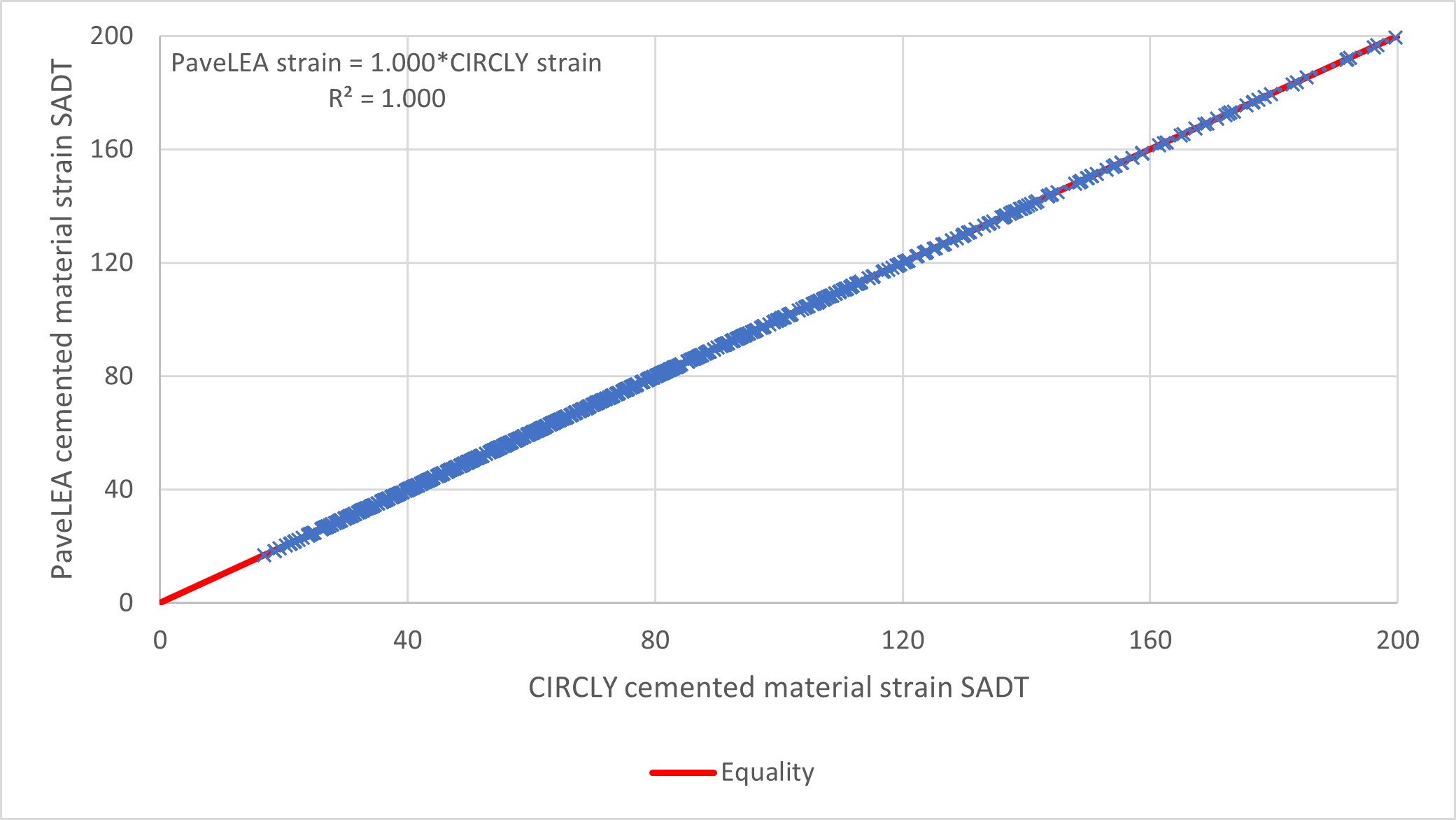

- Asphalt on Cemented Material Pavements

- As per AP-T199-12, the pavement configurations that were compared for asphalt on cemented material pavements had the following inputs:

- subgrade vertical moduli of 30 MPa, 50 MPa, 100 MPa and 150 MPa

- granular thickness of 150 mm with a maximum modulus of 150 MPa

- cemented materials thicknesses of 150 mm, 200 mm and 300 mm with moduli of 2000 MPa, 3500 MPa, 5000 MPa and 10 000 MPa

- asphalt thicknesses of 50 mm, 100 mm, 150 mm, 200 mm and 250 mm with moduli of 1000 MPa, 3000 MPa and 5000 MPa

Note: asphalt strains are not presented as they were either in compression or leading to a fatigue life of the asphalt which exceeds 109 ESAs.

- The figure below shows the calculated maximum tensile strain at the base of the cemented material for a Single Axle Single Tyre (SAST) for PaveLEA vs CIRCLY.

- The figure below shows the calculated maximum tensile strain at the base of the cemented material for a Single Axle Dual Tyre (SADT) for PaveLEA vs CIRCLY.

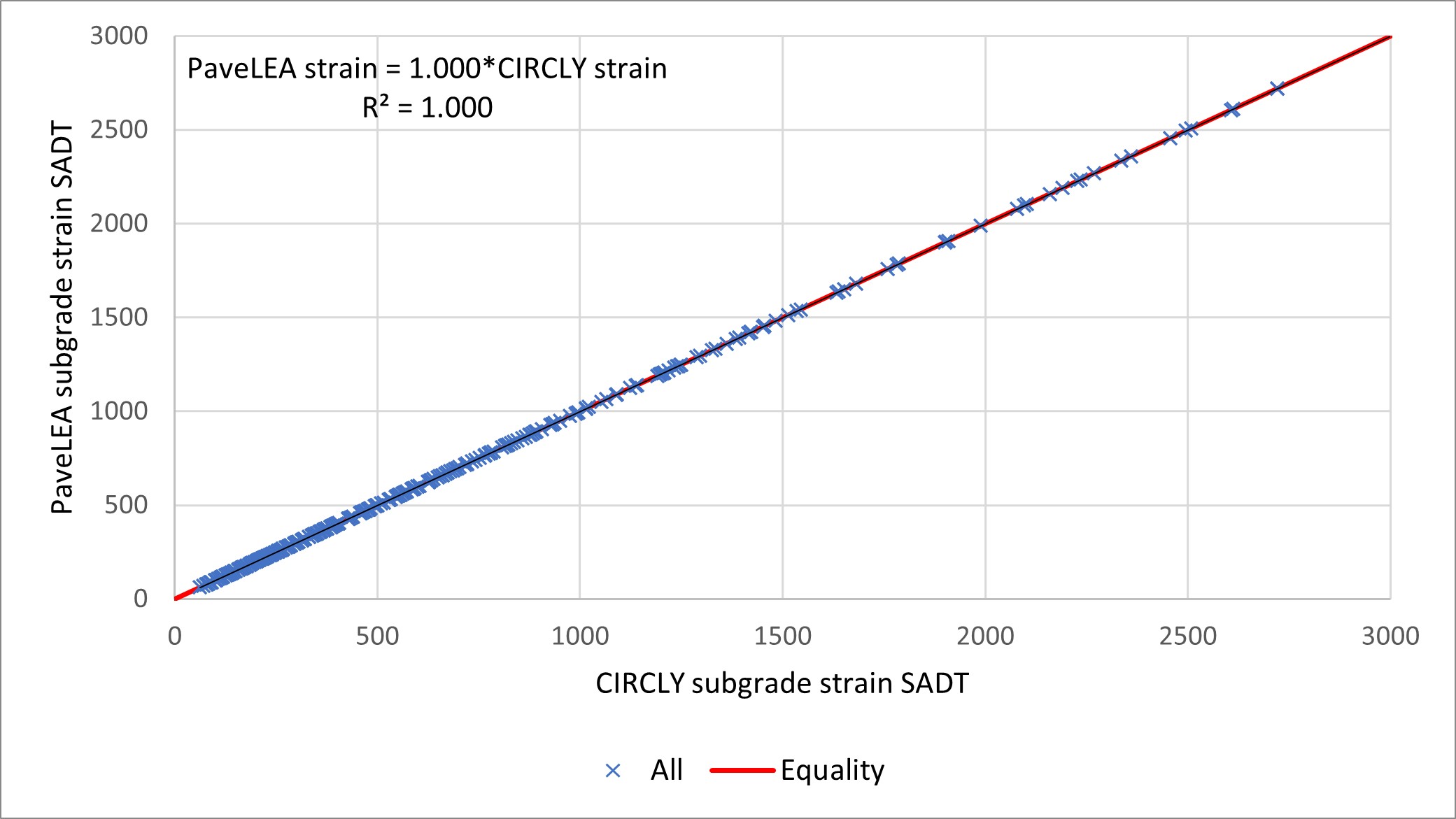

- The figure below shows the calculated maximum vertical compressive strain at the top of the subgrade for PaveLEA vs CIRCLY.